Contact: Jean-Pierre MERICQ

Permanent staff : Marie-Pierre BELLEVILLE, Stéphanie DRUON-BOCQUET, Delphine PAOLUCCI-JEAN-JEAN, José SANCHEZ-MARCANO, Laurence SOUSSAN

Current non-permanent staff: Lies CHENOUFI (PhD)

Former personnel non-permanent : Souhaib QAZI (PhD), Sushumna SHUKLA (PhD), Sandy GOSSET (Ass. Ing.)

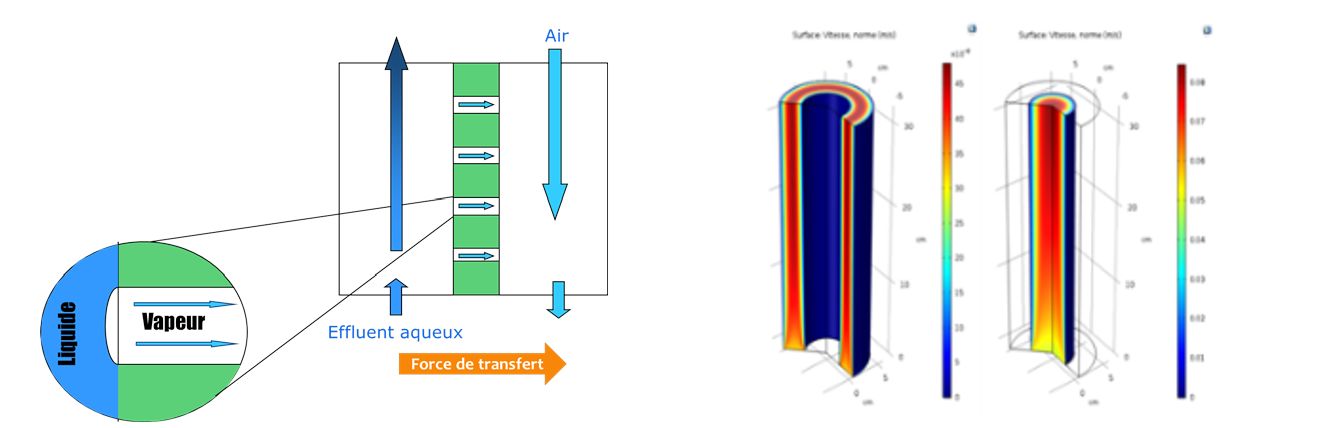

Liquid-gas membrane contactor principle

Flow modeling inside and around a hollow fiber from a membrane contactor

Membrane contactors are processes with a macroporous membrane that allows the contact between two phases (liquid-gas or liquid-liquid) without dispersion of one phase in the other. Indeed, the membrane acts a physical barrier between the two phases, but is not involved in process selectivity, which is achieved by the difference in activity or partial pressure of the compounds across the membrane-supported interface.

Membrane contactor processes can be carried out with different membrane geometries: flat or hollow fibres and can be used in a wide range of applications, including CO2 absorption and capture, removal of pollutants such as H2S, SO2 or NH3, the recovery of dissolved bio methane, liquid oxygenation/deoxygenation, ozonation, gas humidity control, dissolved gas management, removal of organic compounds in liquid phase, fruit juice concentration, desalcoholisation, desalination…

The main objectives of this research theme are (i) to identify and understand the mechanisms/resistances of coupled mass and heat transfer; (ii) to study and limit pore wetting problems; (iii) to model these phenomena in order to optimize the sizing of modules used as membrane contactors; (iv) to successfully carry out the scaling-up from laboratory pilot to semi-industrial pilot for the development of new intensified processes.